What Does Motor Oil Do? - Select Synthetics - AMSOIL Authorized Dealer

Main menu:

- Home Page

-

Products

-

AMSOIL Products

- Shop by Product

- Shop by Equipment

- Shop by Category

-

Product Lookup Guides

- Product Lookup Guides - Home

- Filter Lookup Guides

- Auto & Light Truck Lookup Guide

- Motorcycle & Dirt Bike Lookup Guide

- Harley-Davidson Products Guide

- All-Terrain Vehicle Lookup Guide

- Utility Terrain Vehicle Lookup Guide

- Snowmobile Lookup Guide

- Marine Outboard Lookup Guide

- Personal Watercraft Lookup Guide

- Small Engine Lookup Guide

- Free Product Catalog

- AMSOIL - The Blog

- AMSOIL YouTube Videos

- AMSOIL Performance Tests

- The AMSOIL Newsstand

- AMSOIL Testimonials

- AMSOIL Guarantee

- Safety Data Sheets

- Oil Analysis Services

- Shipping & Product Return

- Safe & Secure Shopping

-

AMSOIL Products

- About AMSOIL

-

Oil Basics

- What Is Motor Oil?

- What Is Oil Viscosity?

- What Does Motor Oil Do?

- Why Does Oil Need To Be Changed?

- How Often Should I Change My Oil?

- When Should I Do My 1st Oil Change?

- Can I Mix Different Oils?

- Lubrication Regimes

- Newtonian vs. Non-Newtonian

- Base Oil Groups

- Motor Oil Specifications

- Service Classifications & Grades

- Oil Evaluation Tests

- Oil Filtration

- What is Oil Analysis?

- Why Synthetics?

- Buy Wholesale

- FAQs

- Contact Us

Oil Basics

What Does Motor Oil Do?

Motor Oil Chemistry Is More Complex Than You Might Think

Today’s oils are complex, chemically engineered compounds that have significantly improved upon refined crude oil. Modern oils are designed and chemically manufactured to achieve specific traits and properties necessary for use in current automobiles.

Modern Motor Oil is a highly specialized product carefully developed by engineers and chemists to perform many essential functions. All of these functions are considered when designing any motor oil, whether it will be synthetic or mineral-based oil.

What does Motor Oil do?

- Lubricates / Reduces Friction

- Cools

- Keeps Engines Clean

- Disperses Combustion By-Products

- Prevents Rust and Corrosion

- Neutralizes Acids

- Seals

- Permits Easier Starting

- Increases Fuel Economy

Figure courtesy of Machinery Lubrication magazine

Lubricates / Reduces Friction

While Motor Oil serves a variety of functions, it’s primarily role is to lubricate the engine. Once an engine is started, the oil must circulate promptly and lubricate all moving parts to prevent the metal to-metal contact that would result in wear, scoring, or seizure of the engine.

Friction is the force that resists relative motion between two bodies in contact. If friction didn’t exist, nothing would ever stop moving. We need friction to function, but there are instances where you want to be able to reduce the amount of friction present.

A reduction in friction leads to less wear on components, easier movement, and reduced energy needs of the system. In fact, some well-designed engine oils can actually increase a car’s fuel economy.

Friction generates heat, so for a lubricant to be successful, it needs to retain its lubricity (slipperiness) even when it gets hot. If a lubricant lacks thermal stability, then it begins to break down when it gets hot, which leads to increased friction.

For oil to be effective it cannot boil away or freeze. In either case, the oil would cease to reduce friction. In the first case, it would simply disappear and leave the moving parts to grind upon one another. In the second case, it would actually increase friction, perhaps to the point of preventing movement altogether.

Motor oils must lubricate and prevent wear in all temperature extremes. Oil that does not flow well in cold temperatures will leave parts of the engine with no protection at start-up (this is when the most metal to metal contact occurs and thus the most wear).

On the other hand, oil that becomes too fluid at high operating temperatures will not be able to maintain an adequate film thickness between moving parts.

Oil flow also refreshes critical additives to the working surfaces. This reserve additive supply includes anti-wear additives, friction modifiers, corrosion inhibitors and others. Lubricant starvation produces elevated heat, which rapidly depletes additives.

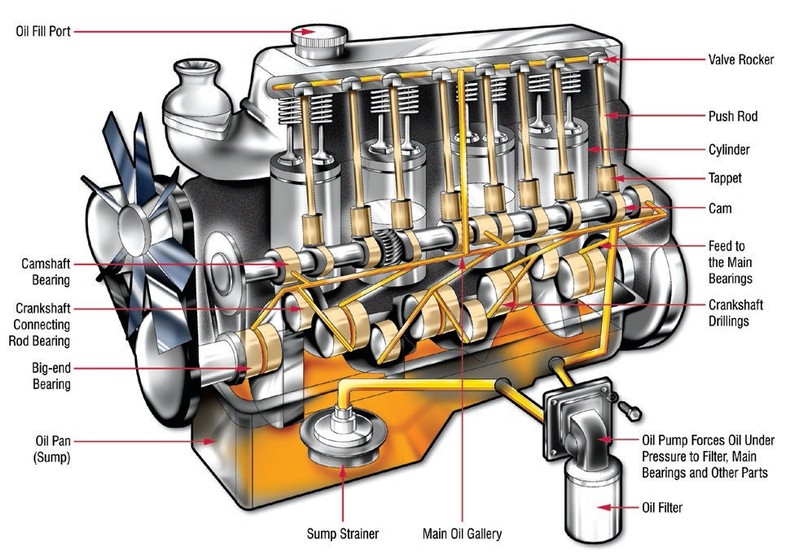

There are three states (or regimes) of lubrication:

- Boundary Lubrication

- Mixed Film Lubrication

- Hydrodynamic/Elastohydrodynamic Lubrication (Full/Thick Film)

Cools

Another essential role of motor oil is to cool the engine. The radiator/antifreeze system is responsible for about 60 percent of the engine cooling that takes place. However, this cools only the upper portion of the engine, including the cylinder heads, cylinder walls and valves. The other 40 percent is cooled by the oil.

Engine heat is created from friction of moving parts and the ignition of fuel inside the cylinder. Oil carries heat away from these hot surfaces as it flows downward and dissipates heat to the surrounding air when it reaches the crankcase.

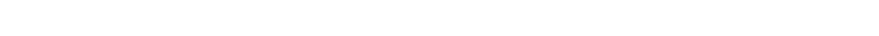

When the engine is at rest, the motor oil sits in the bottom of the engine block in the oil pan (or sump). Upon start-up, an oil pump feeds oil from the pan to the oil distribution system by means of a network of passages, tubes, grooves and holes leading to the engine bearings and other surfaces needing pressurized oil for lubrication.

In some constructions oil is sprayed through a nozzle inside the crankcase onto the piston to provide cooling of specific parts that undergo high temperature strain. Other parts, like the overhead valve system, receive a carefully controlled quantity of non-pressurized oil through splashing or spray.

The oil is directed onto hot surfaces, such as the crankshaft, main and connecting rod bearings, the camshaft and its bearings, the timing gears, the pistons and many other components in the lower portion of the engine that directly depend on the motor oil for cooling.

Lubricating an engine actually requires a very small amount of motor oil compared to the amount needed to ensure proper cooling of these internal parts. The oil pump constantly circulates the oil to all vital areas of the engine.

Keeps Engines Clean

Another important feature of any motor oil related to preventing rust and corrosion is the necessity of keeping engine components clean.

Unburned fuel and soot can mix with water to form sludge and varnish deposits on critical engine parts. Sludge build up may clog oil passages, which reduces oil flow. Varnish build up interferes with proper clearances, restricts oil flow and causes vital engine parts to stick and malfunction. Sludge and varnish can be controlled with the proper additives and can be filtered out of vital engine components.

In performing its lubrication function, some oil must reach the area of the top piston ring in order to lubricate the rings and cylinder walls. However, when exposed to the heat and flame of burning fuel, part of the oil actually boils off.

Modern oils have been chemically engineered to burn as cleanly as possible in order to minimize the harmful deposits left on the walls of the combustion chambers. When excessive deposits build up this can cause ring sticking and breakage, pinging, engine knock or other combustion irregularities that reduce the efficiency and economy of the engine.

Disperses Combustion By-Products

Soot is a by-product of diesel engine combustion. It is black carbonaceous particulate matter, which does not dissolve in lubricating oil, but can be suspended by the oil and removed during an oil change. If soot is not well dispersed it will cause the oil to thicken up and go out of grade.

In addition, soot can agglomerate to form particles large enough to cause abrasive wear and when the soot load of oil gets too high, it settles out and forms sludge. Agglomerated soot and/or highly thickened oil can result in high pressure at the oil filter inlet. This can cause the filter by-pass to open and allow unfiltered oil into the engine.

Engine oils formulated to fight soot are able to disperse large amounts of soot without thickening up. Good soot dispersal stops large particles agglomerating, prevents abrasive wear developing and inhibits the formation of sludge.

Protects Against Rust and Corrosion

For each gallon of fuel burned in an engine, more than one gallon of water is formed. Although most of this water is in vapour form and goes out the exhaust, some condenses on the cylinder walls or escapes past the piston rings and is trapped, at least temporarily, in the crankcase.

This occurs most frequently in cold weather before the engine has warmed up.

In addition to water and the by-products from incomplete combustion of the fuel, other corrosive combustion gases also get past the rings and are condensed or dissolved in the engine oil. Add to this the acids formed by the normal oxidation of oil and the potential for rust and corrosive engine deposits becomes significant.

The life of engine parts depends in part on the ability of the motor oil to neutralize these corrosive substances. Oil helps to stop or prevent corrosion by coating components in a thin layer that protects them from exposure to oxygen and other “oxidizers” that can cause chemical reactions to occur that lead to damage to the surface of a material.

The best known example of corrosion is rust. Rust occurs when iron is exposed to oxygen. Rusting can be increased by exposure to water and salt (as anyone who lives in a snowy region where salt is applied to the roads will know).

Thanks to much research, effective oil-soluble chemical compounds have been developed. These are added to motor oils during manufacture to provide vital protection to engine parts.

Neutralizes Acids

Oil’s ability to neutralize acids is expressed by its Base Number (BN) or Total Base Number (TBN).

As oil is used in service, it becomes contaminated with acids, causing the Base Number to drop over time. The BN measures the reserve alkalinity of oil, which is the ability of an alkali to neutralize the effect of acid formation. The greater the number, the greater the amount of acidic by-products the oil can neutralize.

Synthetics have a much higher Base Number retention than petroleum-based formulations. The longer a lubricant can resist turning to acid, the longer it can be used. The BN is contributed by overbase additives such as detergents.

A high Total Base Number (TBN) is particularly important in extended drain interval oils, such as AMSOIL synthetic oils, because they neutralize acids, and more of them, for a longer period of time. By using oil analysis, you will be able to track the TBN of your oil and determine how much life is remaining.

Seals

The surfaces of the piston rings, ring grooves and cylinder walls are not completely smooth. They feature microscopic hills and valleys that can reduce engine efficiency by allowing combustion pressure to escape into the low pressure area of the crankcase.

Motor oils must fill in these hills and valleys on ring surfaces and the cylinder walls.

This oil film serves as a seal between the contacting surfaces of the piston rings and interior surfaces of the cylinders to separate the combustion chamber in the cylinder head from the crankcase in the engine block, allowing for maximum combustion pressure.

Permits Easier Starting

The ease of starting an engine depends not only on the condition of the battery, ignition and fuel quality, but also on the flow properties of the motor oil.

If the oil is too viscous (thick) at starting temperatures, it will impose enough drag on the moving parts that the engine cannot be cranked fast enough to start promptly and keep running.

Oil that does not flow well in cold temperatures will leave parts of the engine with no protection at start-up (this is when the most metal to metal contact occurs and thus the most wear).

Since cold temperatures thicken all oils, an oil for winter use must be thin enough to permit adequate cranking speeds at the lowest anticipated temperature. It must also be fluid enough to quickly flow to the bearings to prevent wear.

In addition, the oil must be thick enough, when the engine reaches normal operating temperatures, to provide adequate protection, such as maintaining a proper oil film thickness between moving surfaces.

Increases Fuel Economy

A final function of motor oil is in increasing fuel economy.

Various additives such as friction modifiers can allow engines to operate at increased levels of efficiency, resulting in better fuel economy for vehicles.

The use of synthetic motor oil can have a profound impact on fuel economy. Industry tests demonstrate an average conservative decrease in fuel consumption by two to five percent by switching to synthetic lubricants. Synthetic lubricants reduce friction and allow engines to use energy more efficiently.

In a demonstration involving over-the-road trucks an improvement of 6.54% was achieved by switching from conventional lubes to synthetic lubricants (in this case AMSOIL) in the drive train and engine.

Final Thoughts

All of these functions, to some extent, can be performed by both mineral and synthetic oils. However, synthetic oils do not contain many of the impurities that mineral oils do allowing them to perform at higher levels in all categories.

AMSOIL has long recognized the benefits that synthetic oil can offer over a mineral oil. Synthetic fluids exhibit higher tolerances and greater lubricating properties in every aspect of automotive operation.

AMSOIL Synthetic Motor Oils contain the highest quality base stocks and premium additive packages to insure that a vehicle can receive the finest in protection and operate at the highest level of efficiency.

Home Page | Products | About AMSOIL | Oil Basics | Buy Wholesale | FAQs | Contact Us | General Site Map